We’re just getting into what this platform can do.” For example, we can grow collagen on the surface of this plastic by loading it with copper the collagen cells will attract and proliferate on the surface. MiRus, founded in 2016, is developing spinal implants using a proprietary molybdenum-rhenium alloy (MoRe) that is reportedly stronger than other alloys, and therefore uses less material. Kornelis Poelstra, M.D., an orthopaedic and neural spine surgeon and founder of The Spine Center of Excellence at Sacred Heart Hospital in Pensacola, Florida, presented findings from use of the materials. Poesltra highlighted three advantages to the material.

One is its strength and durability compared to other metals like cobalt chrome, titanium and stainless steel.

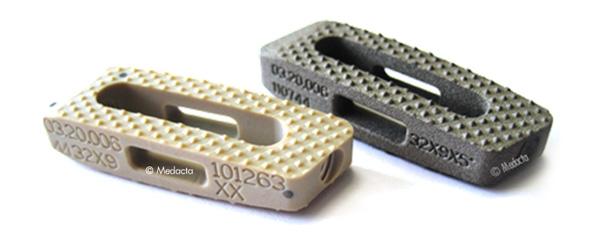

MoRe is two to three times stronger than titanium or cobalt chrome and four times more durable, Dr. This allows MiRus to use less metal, which leads to smaller implants and responds to the move to minimally invasive surgery. Two, MoRe is also hydrophilic, making it friendly to bone ingrowth. “With MoRe, when you put a drop of water on it, it doesn’t stay as a droplet it flattens out quickly, similar to what cells will do if a cell drops on the surface.” “MoRe is about 60% more wettable than titanium, which has now become the standard as compared to metals we’ve used in the past,” he says. Three, MoRe can be shaped via additive manufacturing or subtractive manufacturing processes. MiRus plans to target spinal and orthopaedic degeneration and deformities with its proprietary alloy. The company has developed a platform of spinal implants and surgical navigation, which it plans to begin launching in 2018. “We are in the infancy of seeing what this metal can do,” Dr. “So far, during standard tests, it outperforms cobalt chrome and titanium in every single aspect we’ve looked at-that makes it exciting for where this can go.”Ĭarolyn LaWell is ORTHOWORLD’s Chief Content Officer. Customer-specific Materials with Bioactive Properties “Introduction of the new VESTAKEEP® Fusion product line represents an important step in the strategic development of our portfolio. This work draws upon our decades of expertise in polymer chemistry and on Evonik’s global innovation and production network. That foundation means we can offer patients a one-of-a-kind product and significantly improve their quality of life,” says Marc Knebel, head of the medical systems market segment at Evonik.

0 kommentar(er)

0 kommentar(er)